From the keg to the tap, Carbon Dioxide (CO2) propels your delicious draft beer to its destination—your customer’s glass. But there are two things to keep in mind when you’re setting up your CO2 tank so you can serve beer that is perfectly balanced.

CO2 Beer Pressure Settings

The ideal pressure for CO2 is between 10-15 pounds per square inch (psi) but can vary between temperature and altitude. You may need to adjust your pressure by 1 psi for every 2 degrees temperature or for every 2,000 feet above sea level. Keep in mind that different beer styles will require different psi levels. Wheat, Belgian, and sour beers are poured at higher pressures than ales.

Learn More About Benefits of Beer Gas Blends

How to Measure Your Draft Beer Pressure?

Use your CO2 gauge on the regulator attached to the top of your gas tank to check your psi levels. This lets you know when you need a new CO2 tank and identify any issues in your beer. Your low-pressure gauge shows the psi level your beer is poured. The high-pressure gauge shows the amount of compressed air remaining in the tank. Additionally, if you aren’t sure if your system is balanced, check to see how long it takes to fill a glass. A well-balanced system should fill a standard pint glass in 8 seconds and a gallon in one minute.

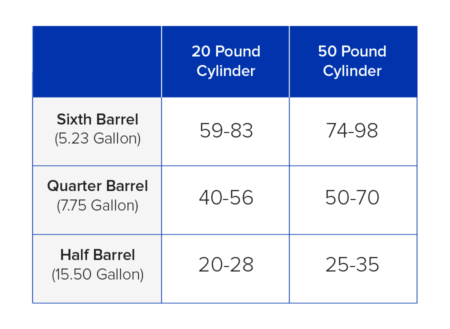

The CO2 Tank to Keg Ratio

Knowing how many CO2 tanks you need helps you get the most out of your beer keg. Follow this guide from EspriGas to keep your system properly balanced and perfectly carbonated.

Learn More About Benefits of Beer Gas Blends

CO2 20-pound cylinder

20-pound cylinder

- Sixth barrel: 59-83

- Quarter barrel: 40-56

- Half barrel: 20-28

CO2 50-pound cylinder

- Sixth barrel: 74-98

- Quarter barrel: 50-70

- Half barrel: 25-35

Ready to Partner With a Reliable Beer Gas Supplier?

EspriGas makes the beverage gas supply process simple. Our network of supply partners ensures that you’ll get the gas you need when you need it. To get started use the link below to speak with one of our experts.

HOW WE MAKE ORDERING SIMPLE

The EspriGas Way

Fulfilling your beverage gas needs should be simple and easy. Our streamlined ordering process will help you get the right amount of gas, on-time with minimal effort.